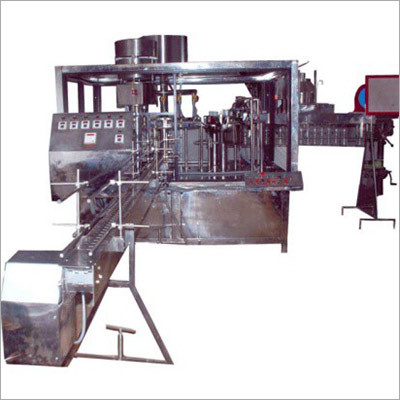

Water Purification Plant

Product Details:

Product Description

A water purification plant, sometimes referred to as a water treatment plant or a water purification facility, is a specialised establishment created to treat and purify untreated water obtained from diverse sources so that it is safe and acceptable for human consumption or other particular uses. A water purification facility's job is to clean up pathogens, pollutants, and other impurities from raw water so that it satisfies regulatory standards for purity.

The main elements and procedures generally used in a water purification plant are listed below:

1. Raw water is obtained from lakes, rivers, wells, or other accessible sources for intake and screening. Large material, including leaves, sticks, and other solids, are screened out of the water during the intake phase in order to protect the equipment farther downstream.

2. Coagulation and flocculation: The water is treated with substances known as coagulants, such as aluminium sulphate or ferric chloride. Through the process of coagulation, these substances help small particles group together to produce larger flocs. Then, flocculants (such as polymers) are added to help produce bigger particles for simpler removal.

3. Sedimentation: In big settling tanks or clarifiers, the water is allowed to settle, allowing the heavier flocs to gravitationally sink to the bottom. Sedimentation or clarifying is a procedure that aids in removing suspended sediments and other particles from water.

4. Filtration: The water is subjected to filtration following sedimentation in order to further eliminate fine particles, any lingering suspended solids, and other contaminants. Depending on the needed amount of purification and the particular water quality, many filter types are employed, including membrane filters, multi-media filters, activated carbon filters, and sand filters.

5. Disinfection: The water is disinfected to get rid of or get rid of any remaining germs, such as bacteria, viruses, and parasites. Chlorination (using chlorine gas or sodium hypochlorite), UV radiation, ozonation, or other suitable disinfection procedures are common disinfection approaches.

6. PH Correction and Chemical Treatment: A pH correction may be required to bring the treated water's pH level to the appropriate range. Depending on the required level of water quality, additional chemical treatments, such as corrosion inhibitors, scale inhibitors, or pH stabilisers, may also be added.

7. Advanced Treatment (optional): Advanced treatment procedures may be used, depending on the water source and the individual treatment objectives. These can be activated carbon adsorption, reverse osmosis, nanofiltration, advanced oxidation processes (AOPs), or other specialised methods to remove particular contaminants or enhance the quality of the water.

8. Storage and Distribution: Before being delivered to users via a system of pipelines, the treated water is first kept in hygienic and secure reservoirs or tanks. The distribution system makes sure that the treated water reliably and safely reaches its intended users.

9. Monitoring and Quality Control: The treated water is continuously monitored and tested throughout the water purification process. To maintain compliance with legal requirements and internal quality standards, parameters like pH, turbidity, residual disinfectant levels, microbiological content, chemical composition, and taste are measured.

The size and complexity of water purification facilities varies depending on various elements like the quality of the raw water, the intended treatment, capacity needs, and particular water supply restrictions. For a water purification plant to operate effectively and dependably, providing the community with safe and clean drinking water or meeting specific water quality requirements, regular maintenance, routine equipment cleaning, and adherence to strict quality control procedures are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Mineral Water Processing Plant' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |