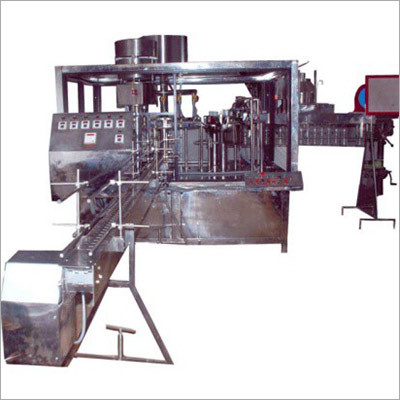

Mineral Water Plant

Product Details:

- Purity Level as per ISI Standards

- Click to View more

Mineral Water Plant Price And Quantity

- 1 Set

- INR

Mineral Water Plant Product Specifications

- as per ISI Standards

Mineral Water Plant Trade Information

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cheque

- 2 Week

- North America South America Australia Eastern Europe Asia Western Europe Central America Middle East Africa

- All India

Product Description

An establishment that processes and packages water from a natural source or a treated water source to ensure its purity and safety for consumption is referred to as a mineral water plant, also known as a bottled water plant or a packaged drinking water plant. A mineral water plant's main goal is to create packaged drinking water that complies with legal requirements and quality standards.

The general steps in the manufacture of mineral water at a typical plant are as follows:

1. Selecting a Suitable Water Source: The first step is to locate a suitable water source. It may be purified water from a municipal supply, a well, a borehole, or a natural spring. Water from the source should be of good quality and include little in the way of pollutants or toxins.

2. Water Treatment: The water goes through a number of processes to get rid of pollutants and make sure it's safe to drink. The therapeutic approaches could be:

- Water is filtered to get rid of bigger pollutants, suspended particles, and sediment.

- Disinfection: To get rid of bacteria, viruses, and other microbes, the water is disinfected using procedures like chlorination, UV light, ozonation, or other suitable ways.

- Reverse osmosis (RO): An RO system may occasionally be used to filter out dissolved minerals and particles for additional purification.

3. Mineralization: To improve the flavour and quality of the water after it has been cleaned and treated, minerals may be added. A few examples of these minerals are calcium, magnesium, and potassium. The mineralization process guarantees a balanced mineral concentration in the water.

4. If sparkling or carbonated water is needed, carbon dioxide gas may be introduced to the water under carefully regulated circumstances to produce bubbles and carbonation.

5. Packaging: Bottles or other containers are used to package the treated and mineralized water. The packaging procedure guarantees cleanliness and guards against contamination. Typically, bottles are composed of glass, food-grade plastic, or other acceptable materials. Automated machinery is used to clean, sterilise, and fill them with water.

6. Quality Control: Throughout the production process, quality control procedures are used to make sure the water satisfies internal and regulatory requirements. Parameters like pH, turbidity, microbial content, chemical composition, and flavour are regularly tested.

7. After the bottles are filled, they are labelled with the necessary information, including the brand name, production date, batch number, nutritional data, and any other necessary information. For marketing and shipping purposes, packing may also incorporate supplementary packaging or shrink-wrapping.

8. Distribution and Sale: Consumers can purchase the packaged mineral water by visiting shops, supermarkets, convenience stores, and other locations. To preserve its quality, the water is transported and kept in carefully regulated environments.

It's critical that mineral water production facilities adhere to all applicable laws, rules, and guidelines regarding water purity, bottling procedures, labelling specifications, and hygiene. For the plant's bottled water to continue to be of the highest quality and safety, regular monitoring, upkeep, and inspections are required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Mineral Water Processing Plant' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |