Packaging Drinking Water Machinery

Product Details:

- Purity Level as per ISI Standards

- Water Source Other

- Automatic Grade Full Automatic

- Drive Type Other

- Click to View more

Packaging Drinking Water Machinery Price And Quantity

- INR

- 1 Set

Packaging Drinking Water Machinery Product Specifications

- Full Automatic

- as per ISI Standards

- Other

- Other

Packaging Drinking Water Machinery Trade Information

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cheque Cash Advance (CA)

- 7 Set Per Month

- 2 Week

- as per customer requirement

- Eastern Europe South America Asia Western Europe Australia North America Central America Middle East Africa

- All India

Product Description

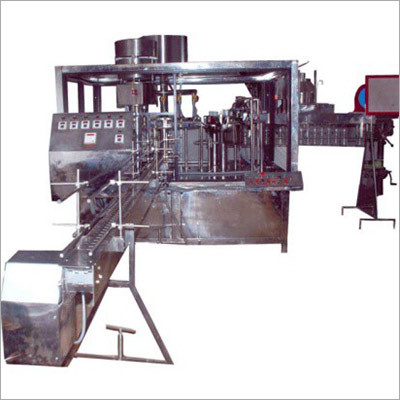

The packaging machinery used to make packaged drinking water typically consists of a variety of tools built to effectively automate the bottling operation.

Here are some typical examples of equipment found at a facility that packages drinking water:

1. Before the bottles are filled with water, they are cleaned and sanitised in a bottle washing machine. To make sure the bottles are clean and free of impurities or pollutants, it usually entails procedures like rinsing, brushing, and disinfecting them.

2. Filling apparatus for bottles: The filling apparatus is in charge of precisely filling the cleaned bottles with the treated and mineralized water. Depending on the particular needs of the business, it may be a filling machine that operates under pressure or under gravity. These devices guarantee accurate filling levels and stop spills and waste.

3. Bottle Capping Machine: The capping machine puts caps or closures to the bottles once they have been filled. The capping step, which ensures good sealing, can be completed by an automated machine that sorts the caps and inserts them on the bottles.

4. Applying labels to the bottles is done with this machine. It can handle applying different label kinds, such as shrink sleeves or adhesive labels. The labelling device makes sure that the labels are applied to the bottles accurately and in alignment.

5. Printing manufacturing dates, batch numbers, and other pertinent data on the bottles is done using a date-coding machine. For the sake of quality control and traceability, it ensures accurate and readable coding.

6. For simpler handling and shipping, bottled water may occasionally be packaged in packs or bundles. A collection of bottles are wrapped securely in plastic film using a shrink wrapping machine, and the film is then heated to shrink it and seal the package.

7. The final packing of the bottled water into boxes or cartons is handled by equipment for packaging and cartoning. They may automatically load the bottles into the boxes in predetermined configurations, resulting in effective and reliable packing.

8. Conveyors and automation systems are crucial to the packaging process because they allow bottles to flow smoothly between various equipment and stages. The movement of bottles is managed by automated systems, resulting in a seamless and continuous process.

It's vital to remember that depending on the plant's production capacity, level of automation, and particular packaging needs, the specific machinery and equipment needed for a packaged drinking water factory may change. To guarantee the quality and safety of the packaged drinking water, the equipment utilised should also adhere to all applicable industry norms and laws.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Mineral Water Processing Plant' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |