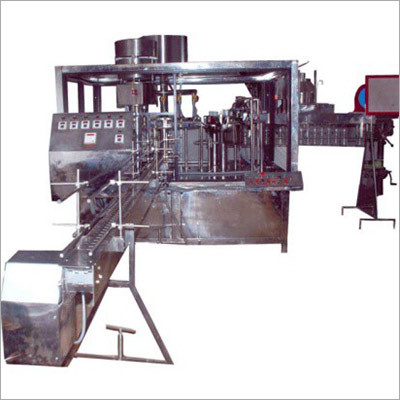

Fully Automatic Jar Filling Machine

Product Details:

- Type Packaging Line

- Material Liquid

- Auxiliary Packaging Machine Type Other

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Drive Type Electric

- Click to View more

Fully Automatic Jar Filling Machine Price And Quantity

- INR

- 1 Piece

Fully Automatic Jar Filling Machine Product Specifications

- 440 Watt (w)

- Electric

- 3 Phase Watt (w)

- Other

- Packaging Line

- Liquid

- Automatic

- 150 Kilograms (kg)

- PLC Control

- Other

- 1 Year

- Yes

Fully Automatic Jar Filling Machine Trade Information

- Letter of Credit (L/C) Telegraphic Transfer (T/T) Cheque

- 4 Piece Per Month

- 1 Months

- 5 Liter to 20 Liter Water Cans

- Central America Eastern Europe Asia North America Australia Western Europe South America Middle East Africa

- All India

Product Description

A specialised piece of machinery called a completely automatic jar filling machine is used to mechanically fill jars or other containers with different items, such as liquids, pastes, or granular solids. The equipment is made to simplify the filling procedure, boost productivity, and guarantee precise and reliable filling quantities.

The main parts and procedures of a typical fully automatic jar filling machine are summarised below:

1. Jar loading: Either manually or automatically, empty jars are loaded onto the machine. The common method of moving the jars through the filling process is to place them on a conveyor belt or onto holders.

2. Filling Stations: The machine has a number of filling stations, each of which is set up to handle a different product or fill volume. These stations can be set up in many ways depending on the needs of the application.

- Filling Nozzles: The product is dispensed into the jars by one or more filling nozzles, one of which is present at each filling station. Depending on the desired production rate and the quantity of jars being filled at once, the number of nozzles is determined.

- Product Supply: The machine is linked to a system that holds the product to be filled, such as tanks or hoppers. To get the product to the filling nozzles, it is pumped or transported.

- Control system: The filling process is regulated by the machine's control system, which guarantees exact volume control and filling operations. The preferred fill volume for each jar can be configured.

3. Filling: The product is distributed into the jars via filling nozzles that fall into them as the jars pass through the machine. Depending on the properties of the product and the desired filling accuracy, the filling process may employ several approaches such as gravity filling, volumetric filling, or weight-based filling.

4. After the jars have been filled, the machine may include a mechanism for placing and sealing the lids. Automatic lid feeding, lid placement, and mechanical or thermal sealing could all be part of this procedure.

5. Capping or Lidding: The machine can be configured with a capping or lidding station if the jar already has a lid. This area makes certain that the jar lids are correctly fastened or sealed. Depending on the jar and lid design, several capping mechanisms may be utilised, such as screw capping, snap-on caps, or induction sealing.

6. Quality Control: Some fully automatic jar filling machines might have quality control features that allow them to check the accuracy of the fill volume, identify and discard jars that were filled incorrectly, or check the integrity of the seal. This guarantees that only jars that have been correctly filled and sealed advance along the production process.

7. Jar Discharge: Following the completion of the filling and capping procedures, the filled and sealed jars are removed from the machine and are now ready for additional processing, labelling, or packaging.

A fully automatic jar filling machine's features and operation might change based on the machine's type, the product being filled, the size and shape of the jars, and the volume of output needed. Advanced machines might have attributes like real-time monitoring, data logging, integrated control systems, automatic jar size changeover, and configurable filling parameters.

To guarantee the effective and dependable operation of a fully automatic jar filling machine as well as to maintain the accuracy and quality of the filled jars, proper maintenance, routine cleaning of machine components, and adherence to hygiene and safety rules are crucial.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Jar Washing Machine' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |