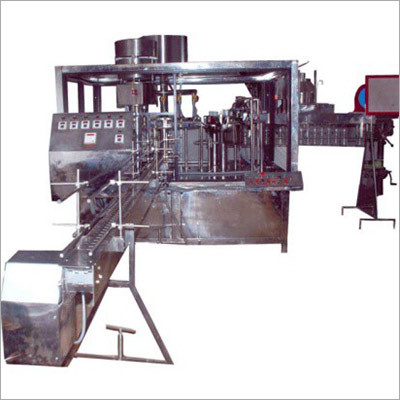

Heat Shrink Bulk Packing Machine

Product Details:

Product Description

A specialised piece of equipment called a heat shrink bulk packing machine is used to package goods in bulk using heat shrinkable material. It is frequently employed in the food and beverage, pharmaceutical, cosmetic, and home product industries. Bulk items can be packaged effectively and securely thanks to the machine's automation of the packaging procedure.

The main parts and procedures in a typical heat shrink bulk packing machine are described in the following overview:

1. Product Feeding: A conveyor system or an automated product feeding mechanism is used to feed the machine with the bulk goods that will be packaged. In preparation for packaging, the products move along the conveyor belt or are kept stationary by a product holder.

2. A roll of heat-shrinkable film is put into the machine's film unwind system, which is a feature. The roll's film is unwound, and it is then directed towards the packaging area.

3. Heat shrinkable film is made into a continuous tube or bag that is then sealed around the bulk goods. To form a sealed package, the film's edges are sealed.

4. Product Enclosure: The film wrapper that surrounds the bulk goods ensures that they are safely contained and safeguarded.

5. After the goods are contained, the film package is passed through a heat shrink tunnel. The film is heated in the tunnel by heat sources such hot air or infrared radiation, which causes it to contract firmly around the items.

6. Cooling system: After the film has contracted, the packages may be cooled down to solidify the film in its contracted state.

7. Cutting and Separation: The film may, if required, be cut and divided into distinct packages in preparation for additional processing, labelling, or packaging.

8. The machine has a conveyor system that transports the packaged bulk goods to the following step of the manufacturing process or to a collection location.

9.Film unwinding, sealing, heat shrink tunnel temperature, cooling, cutting, and conveyor speed are all controlled by the machine's control system. Specific packaging specifications can be programmed into the system, and they can be changed as necessary.

10. Quality Control: To ensure appropriate package construction, film sealing integrity, and package appearance, some heat shrink bulk packing machines may have quality control functions. Inspecting the packages using sensors or cameras to make sure they adhere to quality standards is one way to do this.

Depending on the particular machine model, the kind of items being packaged, and the production needs, a heat shrink bulk packing machine's characteristics and operation can change. Additional features like programmable packing parameters, real-time monitoring, and data logging capabilities may be included in more advanced machines.

To ensure the effective and dependable operation of a heat shrink bulk packing machine as well as to maintain the quality and integrity of the packaged bulk materials, regular maintenance, cleaning of machine components, and adherence to safety regulations are vital.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |