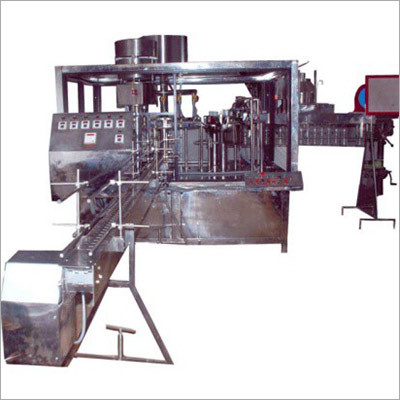

Semi-Auto Bottle Blowing Machine

Price 820000 INR/ Piece

Semi-Auto Bottle Blowing Machine Specification

- Product Type

- Semi-Auto Bottle Blowing Machine

- Computerized

- No

- Automatic

- Yes

- Voltage

- 220 Volt (v)

- Feature

- Full Automatic

- Color

- Blue

- Warranty

- 1 Year

Semi-Auto Bottle Blowing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Semi-Auto Bottle Blowing Machine

Plastic bottle production is carried out on a semi-automatic bottle blowing machine in the manufacturing sector. Plastic preforms or parisons are blown into the proper bottle shape using this device. A semi-automatic machine requires some manual input during the production process, in contrast to completely automated systems.

A semi-automatic bottle blowing machine operates as follows:

1.Plastic preforms are manually loaded into the machine's preform holder or feeding mechanism during preform loading. Typically, preforms are tiny, plastic tubes with a threaded neck that will shape the bottle.

2. The preforms are subsequently transferred to the machine's heating portion. The preforms are heated until they are the right temperature for blowing using infrared lamps or other heating techniques.

3. After being heated, the preforms are moved to a blowing station for stretching and blowing. The preform is stretched vertically, horizontally, or both in this station using a stretch rod or stretch blow moulding device to lengthen it and thin it out.

4. Stretching is followed by moving the preform to the mould, where it is blown into the appropriate bottle shape using compressed air. The mould is made of two parts that fit together tightly around the preform to generate the final shape of the bottle.

5. When the bottle is complete, the mould is opened, and the freshly created bottle is cooled using air or water jets. The bottle is removed from the mould and transported to a collection station or conveyor belt after cooling.

6. Repeat Process: In order to create more bottles, the operator then reloads the machine with fresh preforms.

It's vital to remember that an operator must execute some tasks manually in a semi-automatic process, such as preform loading and opening and closing moulds. The device performs the required blowing, stretching, chilling, and ejection operations. In smaller production facilities or when manual involvement is preferred for certain bottle designs or customization needs, this sort of machine is frequently employed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blowing Machine Category

Fully Auto Bottle Blowing Machine

Minimum Order Quantity : 1 Unit

Automatic : Yes

Warranty : 1 Year

Type : Juice Bottles, Water Bottles

General Use : Industrial

Feature : Full Automatic, High Transparency

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry