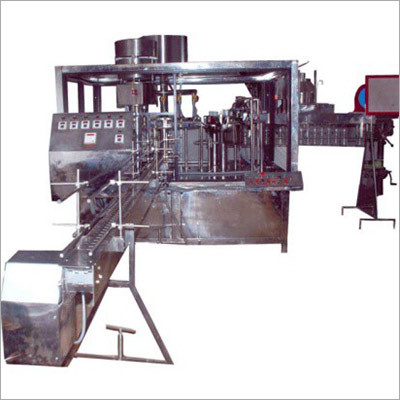

Jar Washing Machine

Product Details:

Product Description

A jar washing machine, often referred to as a jar washer or jar cleaning machine, is a specific piece of machinery used to clean and sanitise jars or containers in a variety of industries, including food processing, pharmaceuticals, cosmetics, and more. The equipment is made to remove pollutants from the jars, making sure they are fully cleaned and prepared for filling or packaging.

The main parts and procedures in a typical jar washing machine are summarised below:

1. Jar loading and unloading: Empty jars can be loaded manually or automatically onto the machine. Usually, the jars are put into holders that go through the cleaning process on a conveyor belt. The cleaned jars are removed from the machine after cleaning.

2. Pre-Rinsing: To remove any loose debris, dust, or residue from the surfaces of the jars, they are first given a pre-rinse with water or a cleaning solution. Prior to the primary cleaning procedure, this step aids in loosening and removing bigger particles.

3. The jars go through the main cleaning stage, where they are put through a number of cleaning procedures to completely remove impurities. Depending on the particular equipment and cleaning requirements, the precise design and number of cleaning stages may change.

- High-pressure water jets are used to effectively dislodge and remove tenacious debris, residues, or particles from the jars. These strong water jets or nozzles are used to spray high-pressure water onto the jars.

- Brushes or Scrubbers: To further loosen and remove dirt or residues, rotating brushes or scrubbers may be used to mechanically scrape the surfaces of the jars.

- Cleaning Agents or Detergents: Cleaning agents or detergents may be used to the cleaning procedure to improve the removal of oily or sticky residues. To make cleaning easier, the detergent is generally sprayed or circulated throughout the jars.

4. Intermediate Rinses: Following the primary cleaning cycle, the jars undergo intermediate rinses to get rid of any last bits of cleaning agent or detergent. To guarantee thorough cleaning, multiple rinse steps may be used.

5. Final Sanitization: At this stage, the jars go through a final sanitization procedure to get rid of any microbiological contamination or potential pathogens. This can be accomplished using a variety of techniques, including steam sterilisation, hot water rinses, or chemical sanitization utilising disinfectants or sanitising solutions.

6. Drying: The jars may go through a drying process to get rid of extra water or moisture, depending on the design of the particular machine. Hot air blowers, hoover systems or other drying processes can be used to accomplish this.

7. Inspection and quality control: Some jar washers include inspection systems built in to look for dirt, leftover particles, or flaws. As a result, only jars that have been thoroughly cleaned can move on to the filling or packaging stage.

Depending on the particular machine model, the demands of the sector, and the kinds of jars or containers being cleaned, jar washing machines can operate and have different functions. Advanced machines may include features like programmable cleaning cycles, automatic loading and unloading, integrated monitoring systems, and cleaning parameters that may be adjusted.

To ensure the efficient and effective operation of a jar washing machine and to maintain the cleanliness and quality of the jars used in manufacturing processes, proper maintenance, regular cleaning of machine components, and adherence to hygiene and safety rules are important.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Jar Washing Machine' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |