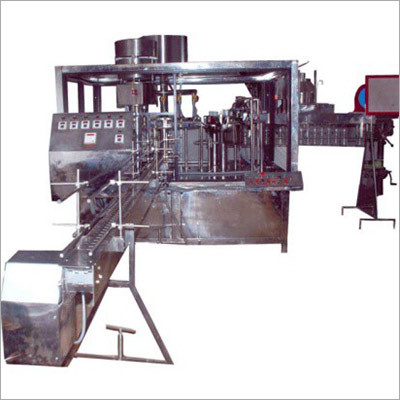

Aeriated Water Filler and Cork Sealer

Product Details:

Product Description

A specialised device used in the beverage industry, an aerated water filler and cork sealer is especially useful for filling and capping bottles of aerated or carbonated beverages like sparkling water, soda, or champagne. The apparatus is made to handle the special demands of filling carbonated beverages while guaranteeing adequate sealing to preserve carbonation levels and prevent leaks.

An overview of the major elements and procedures in an aerated water filler and cork sealer is provided below:

1. Empty bottles are placed onto the device either manually or automatically during bottle loading. In order to fill and seal the bottles, they are normally placed on a conveyor belt or inserted into bottle holders.

2. Bottle Rinsing: The bottles might go through a rinse process before being filled to get rid of any particles, dust, or residue that might be on the bottle surfaces. This makes sure the bottles are clean before being filled.

3. Filling of carbonated beverages entails precisely pouring the beverage into the bottles, minimising foaming, and maintaining the desired level of carbonation. The machine often uses particular filling methods, like counter-pressure filling or vacuum filling, to accomplish this. These methods assist reduce the amount of carbon dioxide gas lost during the filling operation. These methods entail balancing the pressure and preventing excessive foaming by pressurising the bottle with carbon dioxide or by producing a vacuum.

4. After the carbonated beverage has been poured into the bottles, the cork sealing process starts. The bottle necks are inserted with corks, which are frequently used to seal wine or champagne bottles. To ensure appropriate cork insertion and sealing, the machine uses technologies like pneumatic or mechanical corking systems. Depending on the particular requirements of the product, some machines may additionally contain additional stages like sterilising corks or sealing wax.

5. Quality Control: The bottles may go through quality control procedures after being filled and sealed to guarantee adequate filling levels, proper cork insertion, and overall product integrity. Visual inspections, weight checks, or other testing techniques may be used in this to find and remove any flawed bottles from the production line.

The cork sealing procedure begins once the carbonated beverage has been put into the bottles. Corks, which are usually used to seal wine or champagne bottles, are put into the bottle necks. The machine makes use of pneumatic or mechanical corking devices to ensure proper cork insertion and sealing. Some machines may also include extra processes, such as sterilising corks or sealing wax, depending on the specific requirements of the product.

After being filled and sealed, the bottles may undergo quality control procedures to ensure adequate filling levels, proper cork insertion, and overall product integrity. This can be done by using visual inspections, weight checks, or other testing methods to identify and remove any defective bottles from the production line.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Soda Soft Drink Plant' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |