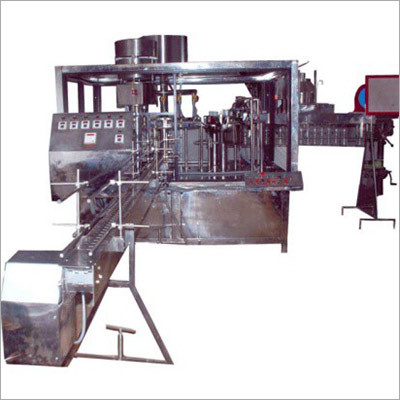

Mineral Water Bottling Plant

Product Details:

- Purity Level as per ISI Standards

- Click to View more

Mineral Water Bottling Plant Price And Quantity

- 1 Set

- INR

Mineral Water Bottling Plant Product Specifications

- as per ISI Standards

Mineral Water Bottling Plant Trade Information

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cheque

- 7 Set Per Month

- 2 Week

- Western Europe Eastern Europe Asia South America Australia Central America North America Middle East Africa

- All India

Product Description

A facility that processes and packages mineral water for commercial sale is referred to as a mineral water bottling plant, sometimes known as a packaged drinking water bottling plant. It entails processing natural or treated water, adding minerals, and putting the finished product in bottles or other containers for distribution and consumption.

The following are the major procedures needed to set up and run a mineral water bottling plant:

1. Find a good-quality water source, such as a natural spring, a well, or a municipal supply that has been treated. Make sure the water is thoroughly tested to make sure it complies with regulations and is safe to drink.

2. Water treatment: Processes are used to clean out contaminants from the water and guarantee its safety and cleanliness. Typical therapy steps could be:

- Using filtering techniques like sand filters, activated carbon filters, or multimedia filters, one can remove suspended particles and debris.

- Disinfection is the process of getting rid of bacteria, viruses, and other germs by using techniques like chlorination, ultraviolet (UV) radiation, or ozonation.

- Implementing a reverse osmosis (RO) system to get rid of dissolved particles and minerals can further purify the water.

3. Mineralization: The process of enhancing the flavour and quality of treated water by adding minerals. By doing this, the mineral content of the water is ensured to be appropriate.

4. Production and Cleaning of Bottles: Purchase food-grade bottles made of glass or plastic. To preserve hygiene, the bottles are produced, sterilised, and cleaned using automated machinery.

5. The cleaned bottles are filled with the treated and mineralized water during the bottling process. Typically, the bottling process entails:

- Rinse the bottles thoroughly in purified water to get rid of any pollutants or leftover debris.

- Filling: Using automated filling devices, transferring the purified water into the bottles. Accuracy is maintained, and contamination is avoided, via this technique.

- Capping: Using closures or caps to properly seal and protect the integrity of the filled bottles.

6. Labelling and packaging: The bottles are labelled with pertinent data, such as the brand name, production date, batch number, nutritional information, and other necessary information, after being filled and capped. For marketing and shipping, packaging may also incorporate supplementary packaging or shrink-wrapping.

7. Implementing quality control procedures at every stage of the production process is essential. To maintain compliance with legal requirements and internal quality standards, regular testing and monitoring of parameters like pH, turbidity, microbiological content, chemical composition, and taste are conducted.

8. Storage and distribution: To preserve the bottled mineral water's purity and freshness, it should be kept in a regulated atmosphere. Following distribution to merchants, supermarkets, convenience stores, and other venues, the bottles are made available for customer purchase.

Regarding water purity, bottling procedures, labelling specifications, and cleanliness, it's imperative to follow all applicable laws and standards. To make sure that the bottled mineral water is safe and of high quality, equipment needs to be maintained on a regular basis and is subject to frequent inspections and quality control checks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Mineral Water Processing Plant' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |