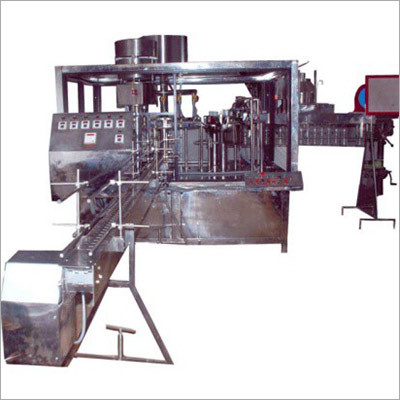

Fully Auto Glue Labeling Machine

Product Details:

Product Description

A specialised tool used to apply adhesive labels to various containers or items is a completely automatic glue labelling machine, sometimes referred to as an automatic adhesive labelling machine. The device is made to automate labelling, offering quick and precise labelling for productive production lines.

An overview of the main elements and procedures in a typical fully automatic glue labelling machine is provided below:

1. The machine is outfitted with a label supply system, which may comprise a magazine or a roll holder for labels. The labels are normally provided in roll form and are pre-printed. Labels are fed into the labelling mechanism from a label roll that has been loaded onto the machine.

2. Container feeding: Through a conveyor system or an automated container feeding mechanism, containers like bottles, jars, or cans are fed into the machine. In preparation for labelling, the containers move along the conveyor belt or are held in position by a container holder.

3. Labelling Mechanism: To apply adhesive labels to the containers, a number of interconnected parts form the labelling mechanism. Depending on the particular machine model, the precise design and operation may vary, but commonly includes the following:

- The labels are dispensed from the label roll and directed towards the labelling point during label dispensing. A labelling head may be used to separate and place the labels for application.

- Application of Glue: The machine uses glue or adhesive to coat the labels. Various tools, such as glue rollers, glue pads, or glue nozzles, can be used to do this. To guarantee appropriate adhesion, the glue is applied uniformly across the labels.

- Labelling Applicator: This person is in charge of carefully applying the labels to the containers. Depending on the needs of the application, it may employ strategies like wrap-around labelling, front and rear labelling, or top labelling.

4. Labelling Adjustment: Depending on the size and shape of the container, the machine may incorporate mechanisms to change the labelling position and orientation. This guarantees exact label positioning and alignment.

5. Container Handling: After the labels are placed on the containers, they are moved to the following step of the manufacturing process by conveyor or container handling equipment. Additional processing, packing, or inspection may be part of this.

6. Control system: The machine has a control system that monitors all aspects of the labelling procedure, including container handling, label application, glue application, labelling applicator movement, and labelling. Specific labelling parameters can be entered into the control system and changed as necessary.

Quality Control: To ensure label accuracy, label alignment, and label adherence, some fully automatic glue labelling machines may have quality control functions. In order to verify that the labelled containers match quality standards, this may utilise sensors or cameras.

A completely automatic glue labelling machine can operate and have different characteristics based on the machine model, the kind of containers being labelled, and the quantity of labels needed. Additional functions like real-time monitoring, data logging, configurable labelling parameters, and automatic label roll replacement may be included in more advanced devices.

To preserve the effectiveness and dependability of a fully automatic glue labelling machine as well as the precision and quality of the labelled containers, regular maintenance, cleaning of machine components, and adherence to safety regulations are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Pet Bottle Labeling Machine' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |