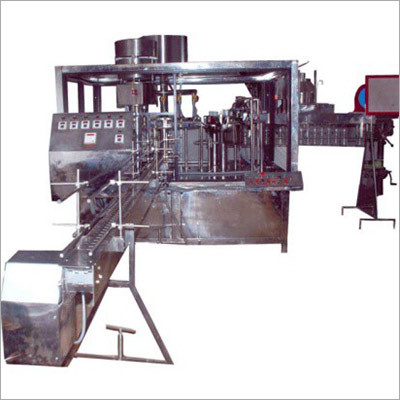

Carbonator Tank with Pump and Motor Assembly

Product Details:

Product Description

A component frequently used in beverage manufacturing and dispensing systems is a carbonator tank with pump and motor assembly, especially for carbonated beverages like soda, sparkling water, and beer. The assembly is in charge of adding carbon dioxide (CO2) to the beverage in order to give it the desired effervescence.

The major parts of a carbonator tank with pump and motor assembly are broken down below along with what they accomplish in the following order:

1. The carbonator tank is a pressurised container that houses the beverage that has to be carbonated. Typically constructed of stainless steel, it is intended to endure the pressure brought on by carbonation.

2. Pump: The beverage is transferred from the tank and forced through the carbonation process with the help of the pump. In order to facilitate the solubility of carbon dioxide into the liquid, it generates the necessary pressure. Depending on the particular needs of the application, positive displacement pumps or centrifugal pumps are frequently employed in carbonation systems.

3. The motor assembly, which is necessary for the pump's operation, is made up of an electric motor and other related parts. The pump is driven mechanically by the motor, allowing the beverage to flow through the carbonator assembly.

4. As the beverage moves through the carbonator tank, a device called a carbon dioxide injector (CO2) injects CO2 into the mixture. It typically consists of a nozzle or diffuser that spreads the CO2 into tiny bubbles, increasing the area where the gas and liquid come into contact to carbonate the beverage.

5. Pressure Regulator: To regulate and maintain the desired pressure inside the carbonator tank, a pressure regulator is frequently incorporated into the assembly. By controlling the flow of CO2 into the tank and avoiding over-pressurization, it provides constant carbonation levels.

6. Valves and Piping: To regulate the flow of the beverage and CO2 during the carbonation process, the assembly contains a variety of valves and piping. These parts aid in guiding the liquid and gas to the intended areas inside the assembly, enabling effective system operation and carbonation.

A bigger beverage manufacturing or distribution system is often connected with the carbonator tank, pump, and motor assembly. A complete carbonation system can be made by connecting it to additional parts such mixing tanks, filters, chillers, and beverage dispensers.

It's vital to remember that a carbonator tank with pump and motor assembly's design and specs might change depending on the application, output, and desired carbonation levels. To preserve the longevity and performance of the assembly and to maintain the desired levels of carbonation in the beverages produced, proper maintenance, regular cleaning, and adherence to safety regulations are crucial.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Soda Soft Drink Plant' category

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |