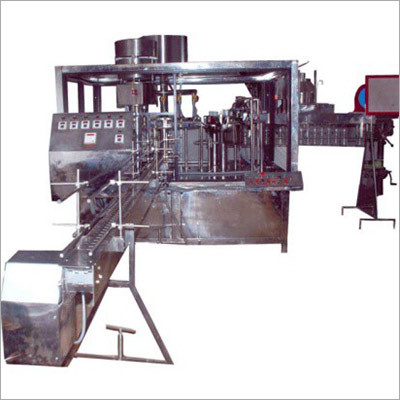

Batch Coding Machine

Product Details:

Product Description

A batch coding machine, often referred to as a date coding machine or a batch printer, is a specialised tool used to print important data, such as batch numbers, manufacturing dates, expiry dates, and other variable data, onto various products or packing materials. It is frequently utilised in sectors like manufacturing, medicines, cosmetics, and food & beverage.

The main parts and procedures in a typical batch coding machine are summarised below:

1. Printing Technology: To mark the desired information on goods or packaging materials, batch coding machines use a variety of printing technologies. The following are the most popular printing technologies:

- Inkjet printing: Using a high-speed, non-contact printing technique, inkjet printers spray small droplets of ink onto a product's or piece of packaging material's surface.

- Thermal transfer printing: Thermal transfer printers transfer ink from a ribbon onto the product or packaging material using a heated printhead.

- Laser printing: Information is etched or marked into the product or packaging material using a laser beam.

- Hot Foil Printing: A coloured foil is transferred onto a product or piece of packaging material using heat and pressure to produce a sharp, long-lasting print.

4. The machine may feature a software interface that enables users to enter variable data, like batch numbers, manufacturing dates, and expiration dates. For automatic data retrieval, some machines can additionally interface with external systems or databases.

5. For accurate positioning of the information on each product or piece of packaging, the machine may have devices to alter the printing position. This may entail mechanical adjustments, sensor-based placement, or adjustable printhead position.

6. Batch coding machines are built to print in real-time as the production process is taking place. They can work quickly and integrate with production lines to keep up with the pace of packing or manufacture.

7. Quality Control: To check the print quality and guarantee the legibility of the printed information, some batch coding machines may have quality control functions. To check the readability and correctness of the printed codes, sensors or cameras may be used.

8. Batch coding devices can be utilised as independent equipment or integrated into current production processes. They can be coordinated with other pieces of machinery, such filling or packaging units, to guarantee accurate coding at the right point in the workflow.

Depending on the exact machine model, the kind of products or packaging materials, and the manufacturing needs, a batch coding machine's specific characteristics and operation may change. To guarantee the proper operation and longevity of the batch coding machine, as well as the accuracy and compliance of the printed information, regular maintenance, periodic ink or ribbon replacement, and adherence to safety requirements are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |